AliNOX

HDP AliNOX was developed specifically for applications on stainless steel, CoCr-alloys, CuBe-alloys, Al, titanium and is optimized to prevent the adherence of work-material to the coating. With a moderate microhardness, high toughness and high coating density, AliNOX shows great results in dry hard milling and in minimal lubricant milling of steels with 50-64 HRC.

HDP AliNOX has good anti-abrasive, anti-sticking properties and avoids microcrack formations on the coating. It achieves excellent results in processing softer materials like aluminum and copper, reducing friction and therefore causing minimal microcrack formation.

Specifications

| Coating material: | AlTiCrN based |

| Colour: | Anthracite |

| Coating thickness [µm]: | 0.5-4 |

| Coating temperature [°C]: | < 500 |

| Nanohardness according to ISO 14577 HIT [GPa]: | 32 ± 2 |

| Max. application temperature [°C]: | 1100 |

Application

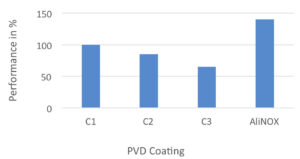

Slot milling stainless steel:

| Material: | DIN 1.4301 |

| Tool: | Hard metal, 4Z, D=6.0 mm |

| Rotations/min: | 6366 rpm |

| Cutting speed: | 120 m/min |

| Cooling: | Emulsion |

| C1, C2, C3: market competitors: |  |

All values are approximate and dependent on the application and on the ambient and test conditions.